Bearing Vibration Monitoring Equipment

Knowing what to listen for.

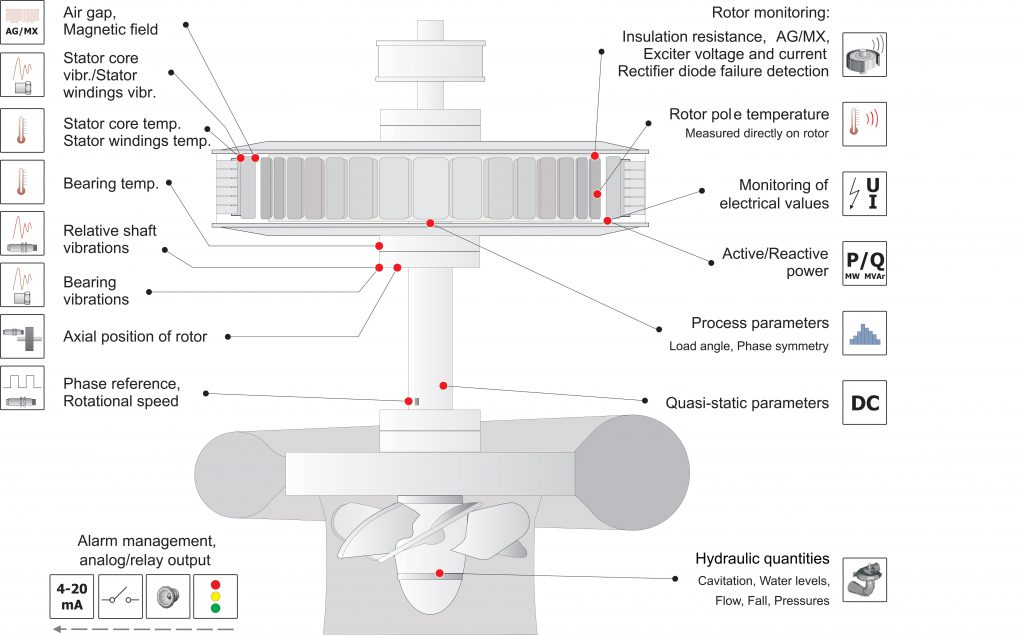

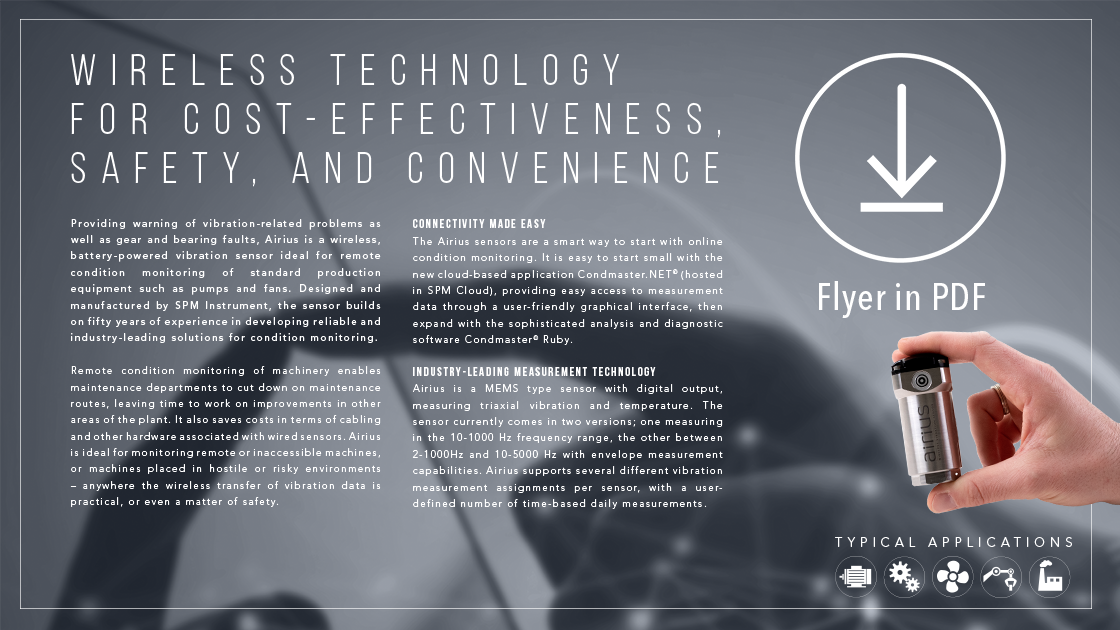

Bearing vibration monitoring equipment. Power transmission seals. Physical characteristics such as temperature rating size and connector orientation are also considerations. Excessive vibration in machinery can cause various types of issues such as energy losses quality deficiencies work environment problems and reduced production speed. The range of vibration sensors offered is wide as a vibration sensor has many different characteristics that may vary including measurement related factors such as frequency response sensitivity and accuracy.

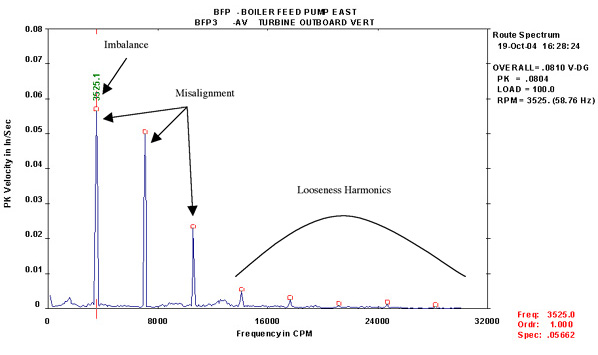

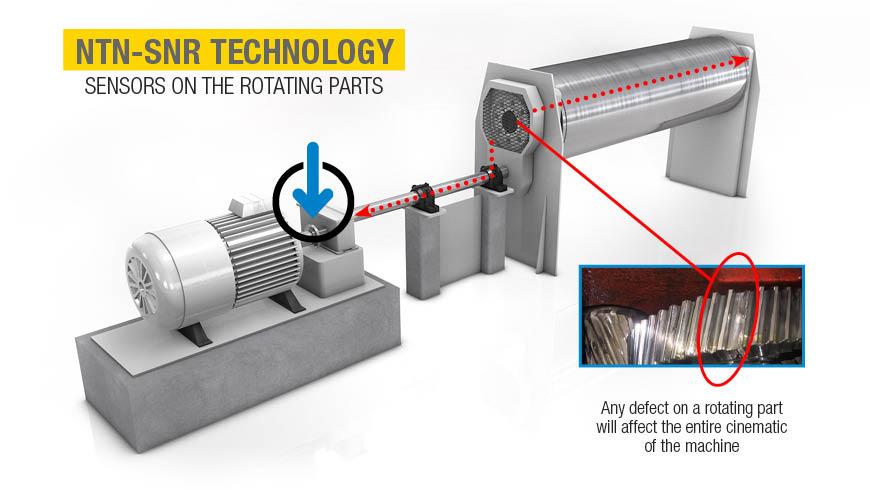

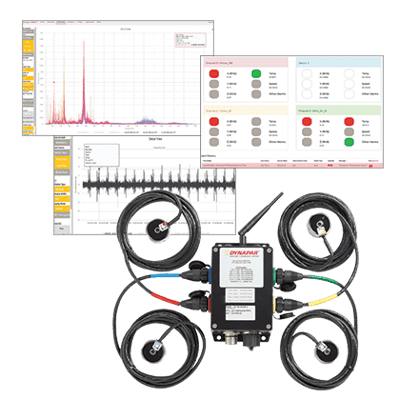

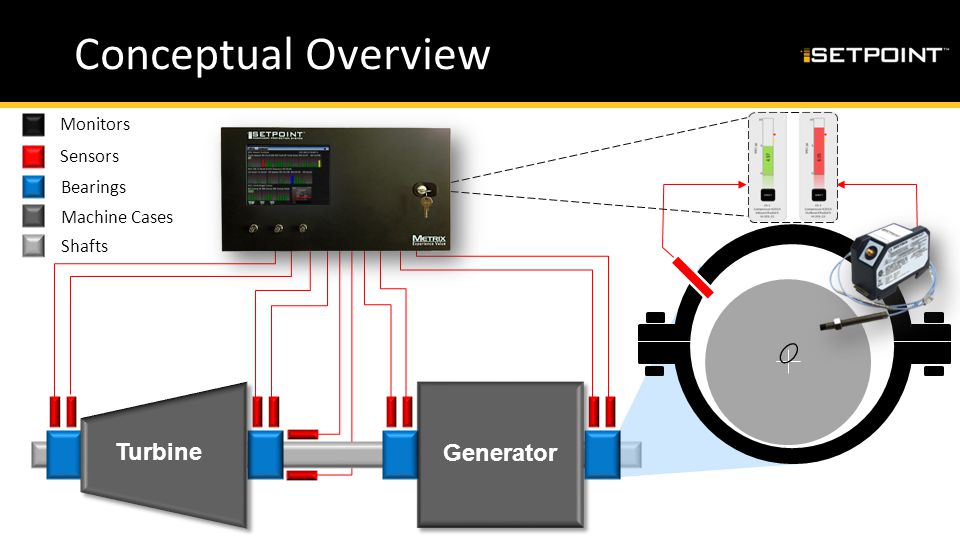

Studying vibration measurements allows teams to discover imbalance looseness misalignment or bearing wear in equipment prior to failure. Vibration transmitters and sensors detect damaged bearings unbalance in drives and rotating machine parts. When to put this knowledge to use. Vibration monitoring devices use accelerometers to measure changes in amplitude frequency and intensity of forces that damage rotating equipment.

New vibration monitoring system with wireless transmission and long battery life are now replacing the. Magnetic bearings and systems. High power led stroboscope compact easy to use stroboscope with 7 ultra bright leds for visual inspection of running machines skf offers a wide range of portable tkrs. Successfully using this programme enables the repair of problem components prior to failure.

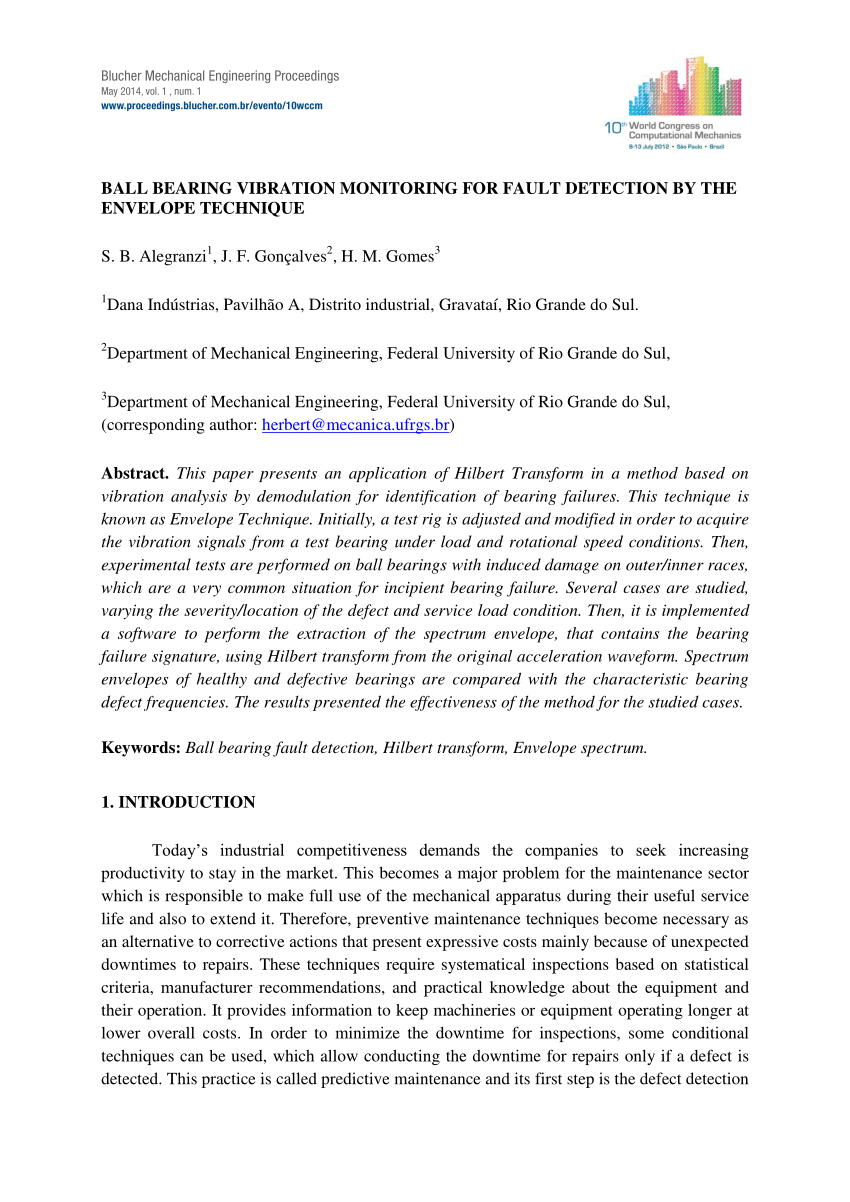

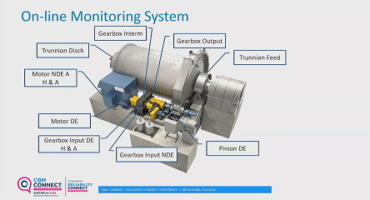

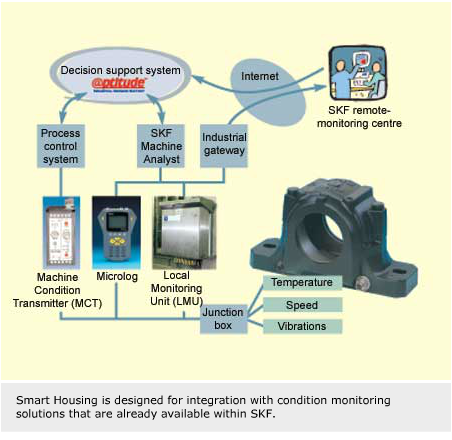

A vibration monitoring system is a set of tools used to measure one or more parameters in order to identify changes in the behavior of the machinery in fact the main purpose of these systems is to help in scheduling the maintenance activities based on a process called predictive analysis. While basic requirements on a bearing like stiffness load capacity speed limit and service life play a critical role in applications low noise and vibration are becoming even more important. We use the latest and most innovative technology and tools for condition monitoring asset. A noisy application might be caused by wavy bearing components local defects in the rings and balls or by dirt particles in the bearing.

Accompanying the fundamentals of machinery and equipment vibration powerpoint presentation materials are several white papers that explain aspects of bearing vibration condition monitoring industrial equipment vibration data collection and measurement of vibration and are used to suppliment various of the seminars and provide a thorough. How to interpret it. The ifm product range includes vibration transmitters vibration sensors accelerometers and evaluation electronics. The key to a successful condition monitoring programme includes.

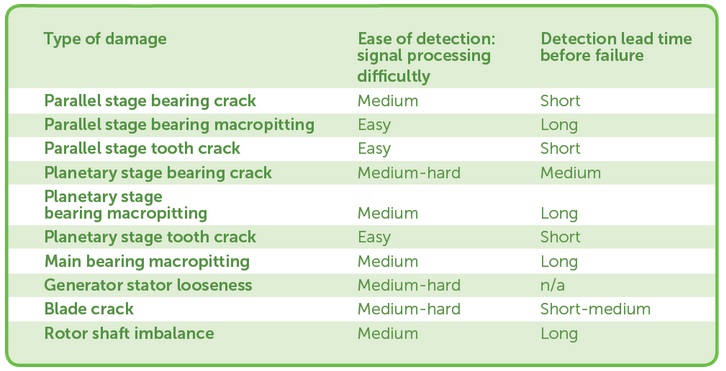

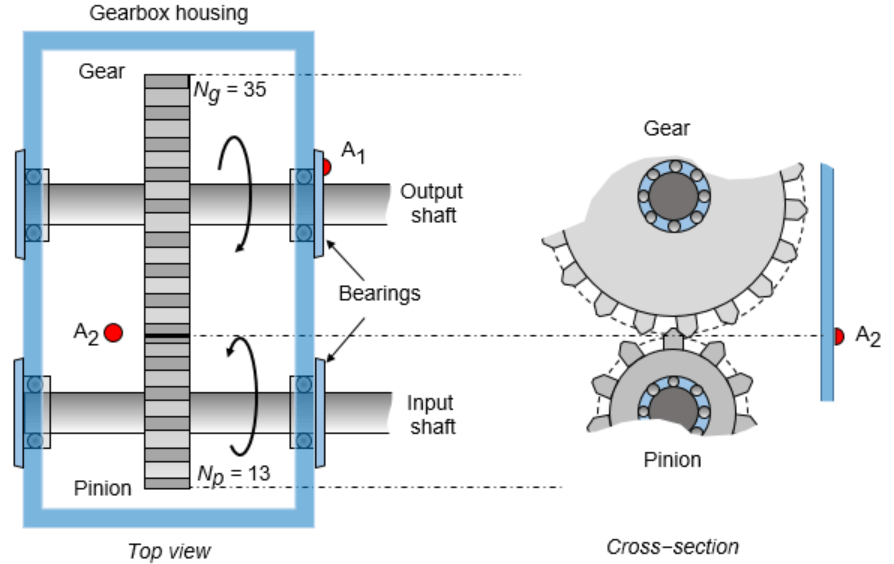

Vibration signals from these types of equipment can be very complex as they often contain a number of different bearing types and gears which can include multistage planetary systems. At times this can make the detection and diagnosis of a problem very difficult and often several different techniques may have to be used to diagnose a problem.

-1-LAV1.jpg?v=1)