Bearing Ring Manufacturing Process

To make the bearing ring and roller be in accordance with the design requirements in size and shape precision.

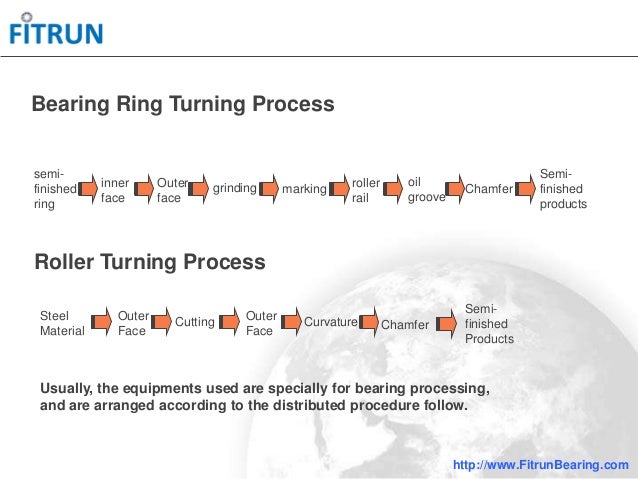

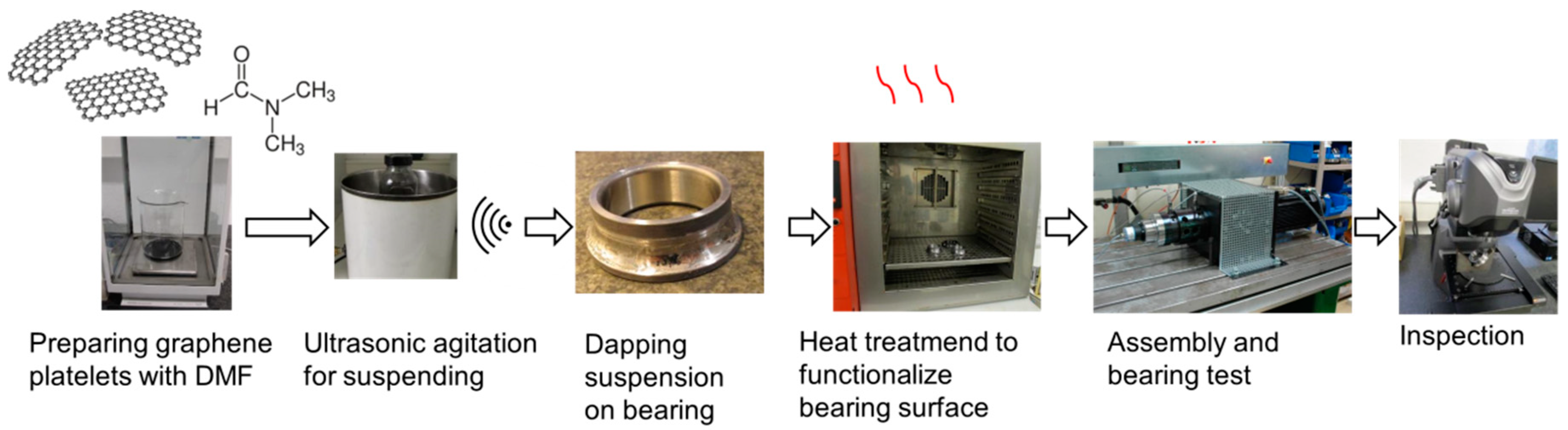

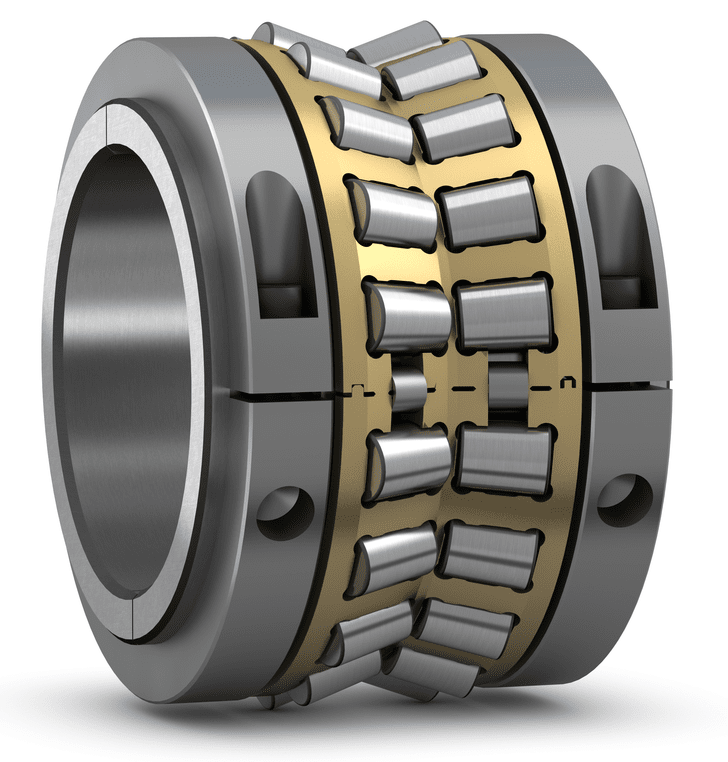

Bearing ring manufacturing process. To prepare qualified rings and rollers for bearing assembly. Manufacturing process of deep groove ball bearings. Grinding grinding is the final processing of bearing ring and roller it is called finished product processing. Grinding is the final processing of bearing ring and roller it is called finished product processing.

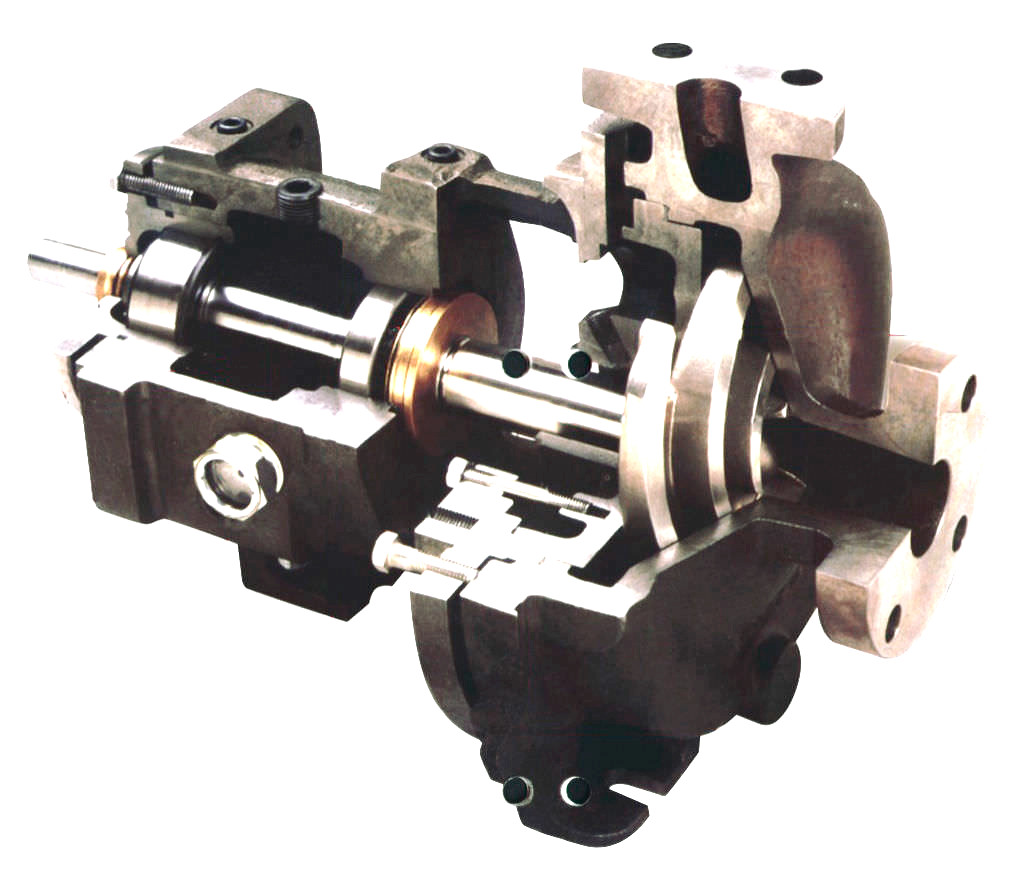

The manufacturing process used to manufacture a ball bearing s inner and outer rings is almost identical. Since they are both rings of steel the process starts with steel tubing of an appropriate size. Races 1 both races are made in almost the same way. Outer ring faces are stamped with bearing number and manufacturer information.

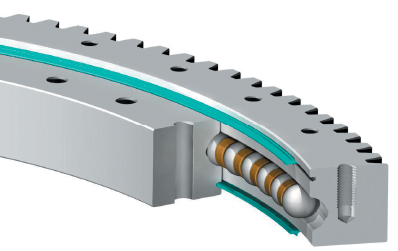

Slewing bearing manufacturing process 1 raw ring 2 machining turntable 3 gear cutting 4 hardening 5 drilling 6 nose ring 7 supporting ring above and retaining ring below 8 assembly of all 3 rings 9 slewing bearing with outer gearing. The following shows the sequence of events of the ring rolling process the part is commonly started as a metal bar cut to a certain length. The main purposes of grinding process. Automatic machines similar to lathes such as screw machines use cutting tools to cut the ring to the basic shape leaving extra material for machining.

As part of the spherical plain bearing manufacturing process the outer ring is fractured to complete bearing assembly. To prepare qualified rings and rollers for bearing assembly. Jesa strives to reduce the number of operations by doing multiple operations on the same tailored machine to increase flexibility and reduce production time. The rings start out as tube stock.

Common items produced by this process in manufacturing industry today include rings for machinery aerospace applications turbines pipes pressure vessels roller and ball bearing races. 3 is a manufacturing process diagram of the outer ring according to an embodiment of the present invention. To make the bearing ring and roller be in accordance with the design requirements in size and shape precision. The main purposes of grinding process.

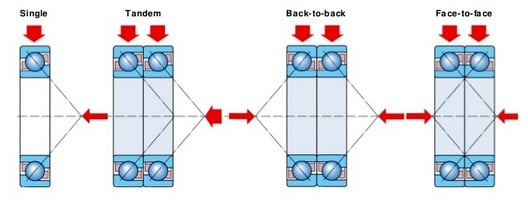

The outer race the rolling balls the inner race and the cage. The manufacturing of a ball bearing is much more complex than we can imagine. Hereinafter a method of manufacturing an outer ring of a ball bearing according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings. Manufacturing process of deep groove ball bearings.