Backing Rings For Pipe Welding

Backing rings can be either round or square and are made typically from rubber or a metal such as chrome carbon steel or aluminum.

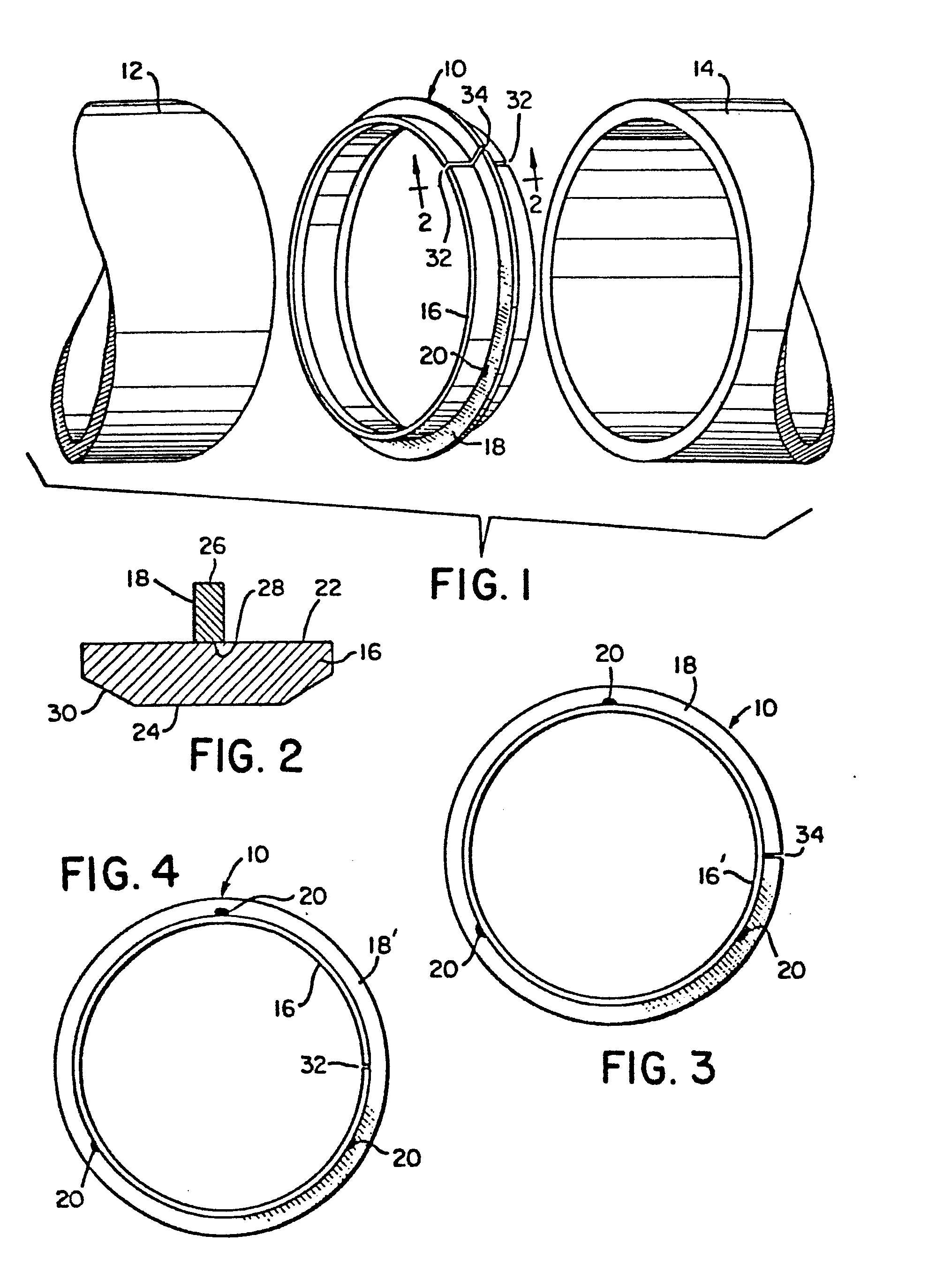

Backing rings for pipe welding. The exact choice of ring depends on the application it is intended to be used for. After some time these crevices will trap bacteria. The patented nubs automatically set the weld gap for the root pass. Backing rings may also be referred to as an anti extrusion ring or backup ring.

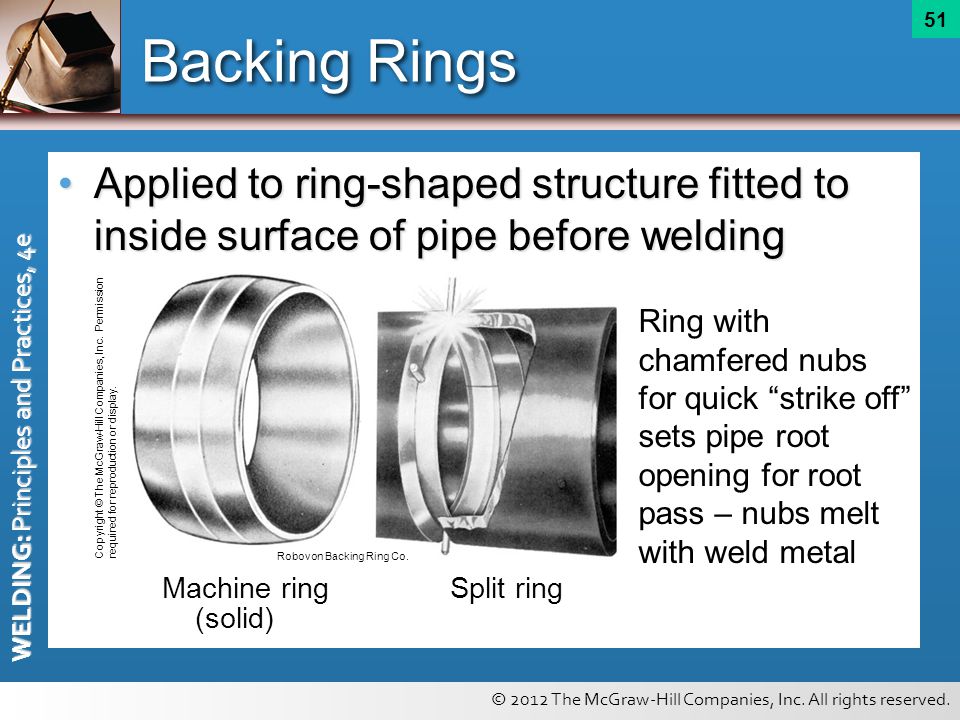

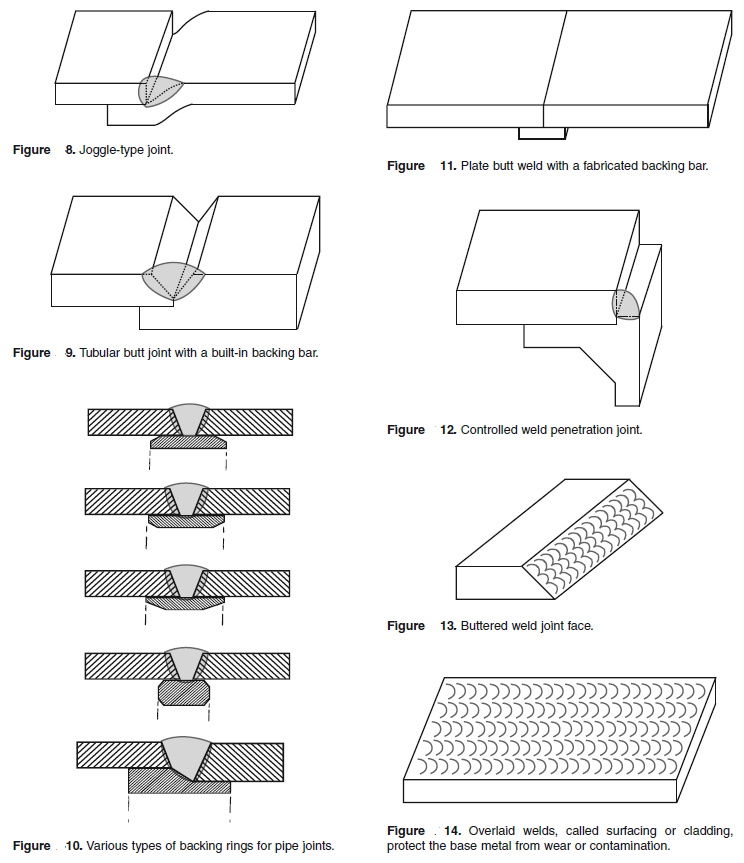

They allow complete penetration and fusion of the weld and radiograph perfect certified welds. Splicers eliminate the need for tack welding while allowing complete weld penetration. Splice rings also called backing or chill rings allow fast alignment of pipe in the field. If you are not familiar with backing rings and want to have this skill to help you at your current job or a future job then this video is for you.

2800 ft of pipe. It has the disadvantage of leaving very small cracks and crevices not seen by the naked eye. Robvon commercial backing rings are designed for quick easy alignment of pipe tube fittings and valves and assure precise close tolerance fit up. When applying the backing ring it is.

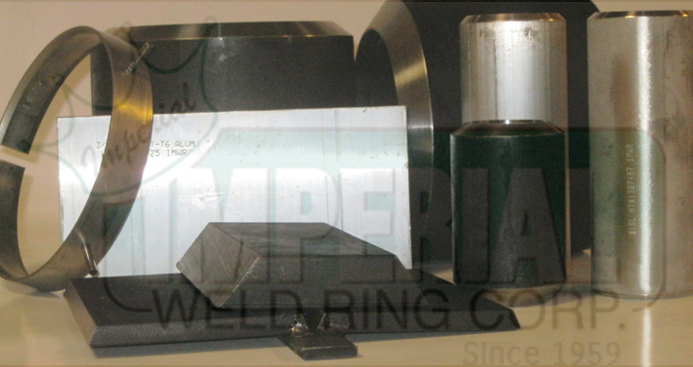

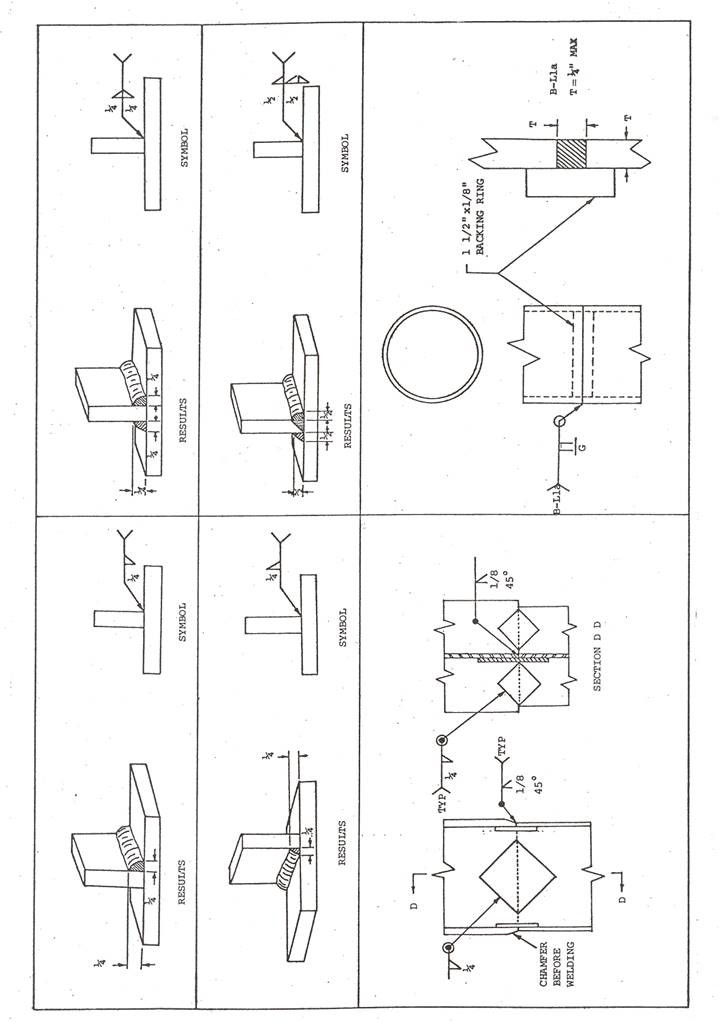

A pipe joint backing ring supports and aligns the two pipes to make it easier for the worker to weld and fit it correctly. This project was for a penstock system down stream pressure was 450psi all xrays were good. Imperial weld ring provides weld backing chill rings in types including long and short spacers pressed type spacers ridge type continuous spacers and flared pipe end. Also they prevent metal slag from obstructing the inside of the pipe.

There are many types of backing rings including plain rings machine welded rings and gasket rings. With our 25 years of expertise we can tell you exactly which ring will fit your installation perfectly. Imperial weld ring corp provides metallic welding products including weld backing rings precision machined rings and fittings consumable weld inserts and weld test coupons. Have used the backing rings on 12 pipe with the spacer pins and they worked great.

A backing ring is applied by welding it between two pipes during the connection process.