Acid Dip Tank Operation

Osha incorporates the following design standards by reference.

Acid dip tank operation. This is acid is used for rust removal and neutralization of the paint removal chemicals. 1910 124 b 5 when you use mechanical ventilation it must draw the flow of air into a hood or exhaust duct. A ansi z9 2 1979 fundamentals governing the design and operation of local exhaust systems. Typical dip tank operations.

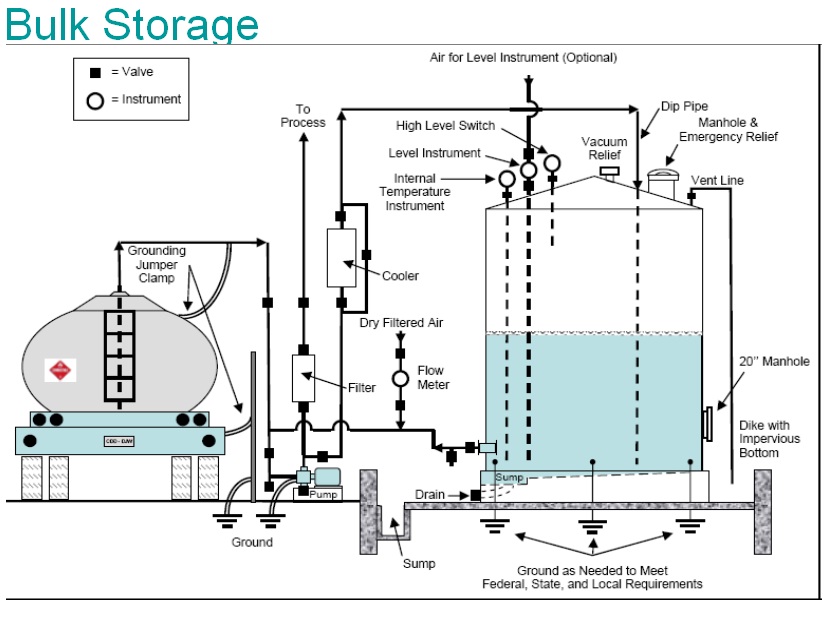

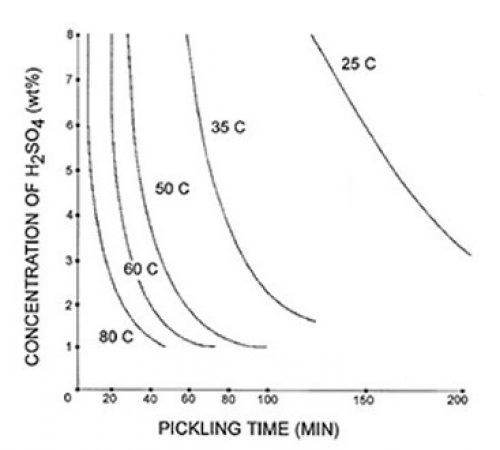

Revivation uses a gentle heated alkaline non acid and non destructive solution. You are not covered by this rule if your dip tank operation only uses a molten material e g molten metal alloy or salt. Acid pickling removes the iron oxides or scales from the steels surface to expose a bare area and permit a galvanized coating to form upon immersion in a molten zinc bath. Containers being used for storing flammable liquid not of the approved type.

This is not an acid dip thereby avoiding warping or thinning of the metal. This is a total immersion process using a two tank system. Ansi z9 1 1971 practices for ventilation and operation of open surface tanks and nfpa 34 1966 standard for dip tanks containing flammable or combustible liquids. C acgih s industrial ventilation a manual of recommended practice 22nd ed 1995 or d.

The following checklist applies to dip tanks and any vapor area containing dangerous quantities of flammable vapors addressed in 29 cfr 1910 124 126. In a galvanizing plant steel will be pickled in an acid tank after the degreasing operation and before pre fluxing. Acid tanks are often used to etch metal materials in order to make them thinner. 1910 124 b 5 when you use mechanical ventilation it must draw the flow of air into a hood or exhaust duct.

The first tank degreases and loosens the paint bondo and undercoating. We use phosphoric acid in our dipping process. The character of metal materials can be changed in dip tanks through processes such as electroplating. Then with a pressure water wash all paint grease and.

Although this checklist is not all inclusive it may be used as a. Ansi z9 1 1971 practices for ventilation and operation of open surface tanks and nfpa 34 1966 standard for dip tanks containing flammable or combustible liquids. The good thing is you don t have to worry about non neutralized acid seeping out of a crack later and ruining a paint job. Acid dip tank operation no quick drench or flushing capability for body or eyes.

They use non acid dipping that does as good a job as the acid dipping. Changing the character of an object.